Description

Miller® XMT® 350 MPa Multiprocess Welder 907366

The Miller® XMT® 350 MPa is a 350 amp multiprocess welder with built-in Pulsed MIG programs for steel, high tensile steels and aluminum. Miller’s exclusive SharpArc® give you total control of the arc cone shape, puddle fluidity and bead profile, while in the pulsed MIG welding mode. Auto-Line™ power management automatically detects 208 to 575 volts, single or three-phase input power and adjusts the XMT 350 MPa to optimize performance.

Processes

- MIG (GMAW)/Pulsed MIG (GMAW-P)

- Stick (SMAW)

- Flux Cored (FCAW)

- Air Carbon Arc (CAC-A) Cutting and GougingApplications

Manufacturing Industrial

Construction

Shipbuilding

Railroad

Truck and Trailer Manufacturing

Fabrication

Repair Shops

Rental FleetsFeatures

- XMT® 350 MPa expands the process capability of the XMT® Series, with built-in Pulsed MIG operation. MPa stands for MIG, Pulse, advanced arc control. The advanced arc control provides:

Improved pulsed MIG welding.

More control over the puddle and weld bead using SharpArc®.

More robust and stable arc at very low arc lengths.

Reduces heat input

Welds on a wider range of material thicknesses.

- Sharp Arc® on the XMT® 350 MPa:

Can handle virtually any welding job, including those hard-to-weld alloys found at power generation plants and shipbuilding facilities.

A low setting gives a more fluid puddle and a flatter bead appearance.

A high setting gives a less fluid puddle and a ropier bead appearance.

Can be adjusted to help customize the arc for the type of shielding gas being used.

- Auto-Line™ Power Management technology allows for any input voltage hook-up (208-575V) with no manual linking, providing convenience in any job setting. Ideal solution for dirty or unreliable input power.

- 350 amps of welding output at 60% duty cycle enables improved deposition through using larger diameter electrodes common in construction applications.

- Available with Dinse or Tweco-style output connectors .

- Power factor of .95 enables smaller fuses/breakers and primary wiring. Primary amperage draw at rated output is 25% less than the competition.

- Exceptional electrical efficiency. At 400 amps, efficiency is 87.24%, this helps to reduce the utility bill or fuel supply required to weld.

- Inverter arc control technology provides greater puddle control for superior 6010 Stick electrode performance.

- Auto Remote Sense enables unit to automatically use remote control if connected to remote control receptacle.

- Reduced OCV operation – an internal dip switch enables reduced open-circuit voltage Stick welding capability. OCV is typically below 15 volts.

- Process selector switch reduces the number of control setup combinations without reducing any features.

- Large, dual digital meters are easy to view and presettable to ease setting weld output.

- Lightweight, aerospace-grade aluminum case offers protection with the benefit of reduced weight.

- Wind Tunnel Technology™ Internal air flow that protects electrical components and PC boards from dirt, dust, debris… greatly improving reliability.

- LVC™ Line Voltage Compensation Keeps output of the power source constant regardless of fluctuation in input power +/- 10%.

- Fan-On-Demand™ Internal power source cooling system that only works when needed, keeping internal components cleaner.

- Adaptive Hot Start™ for Stick Automatically increases output amperage at the start of a weld should the start require it and prevents the electrode from sticking and creating an inclusion.

- Lift-Arc™ Simply touch the tungsten to the work piece and the arc is initiated instantly and automatically without the use of high frequency.

- Optional 115 VAC auxiliary power provides 10 amps of circuit-breaker-protected power for water circulators, etc.

Comes complete with

- Dinse cable connectors (2)

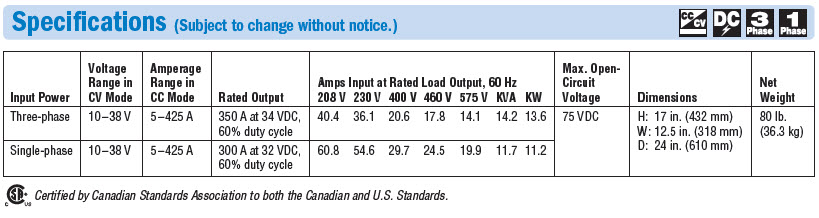

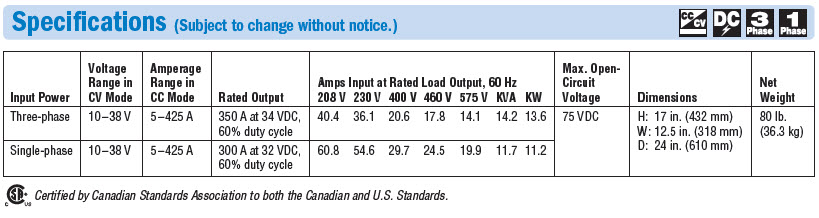

![]()

Reviews

There are no reviews yet.