Get 10% OFF your first order CODE: wlc10off

Get 10% OFF your first order CODE: wlc10off

$7,350.00 Original price was: $7,350.00.$6,364.00Current price is: $6,364.00.

Miller® ArcReach® 16 Wire Feeder 301619

The Miller® ArcReach® 16 Wire Feeder is a heavy duty MIG/Flux-Cored wire feeder that has full remote voltage and amperage control without the use of a remote control cable. The secret to this technology is built-in circuitry in both the ArcReach 16 feeder and your Miller ArcReach welder that passes remote control signals through the welding leads, eliminating the need for costly remote control cables. ArcReach remote control distance is limited only by the length of your welding cable leads. ArcReach allows your MIG or Flux-Cored welding operation to take place further away from the welding power source and reduces downtime and costs by giving the operator full remote voltage AND amperage control capabilities at the site of the weld, without using expensive remote control cables. The ArcReach 16 MUST be paired with a Miller ArcReach welder.

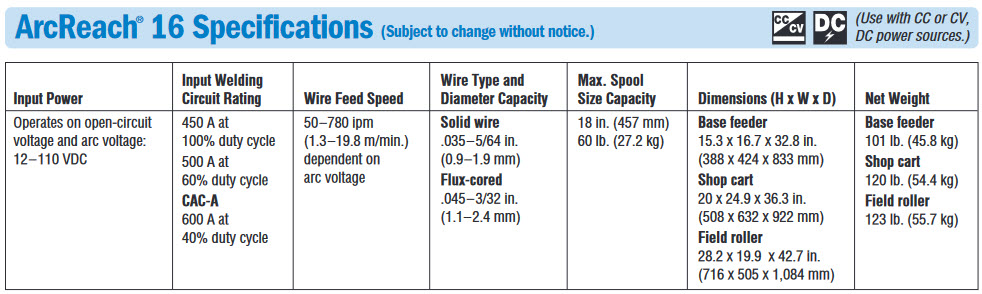

The ArcReach 16 wire feeder has up to a 500 amp welding capacity. It also features an integrated gouging stud for air-carbon arc gouging up to 600 amps. The simple user interface allows for easy switching between MIG, Flux-Cored and gouging processes.

![]()

Processes

Applications

Industrial Applications

Shipbuilding

Construction

Heavy Manufacturing

Features:

![]()

Comes Complete With

Get a FREE Bernard® Q4015AE8IMC MIG gun with the purchase of this ArcReach™ 16 wire feeder. While supplies last. (No substitutions allowed.)

Bernard® Q400 MIG Gun Q4015AE8IMC

Features

Specs

Reviews

There are no reviews yet.